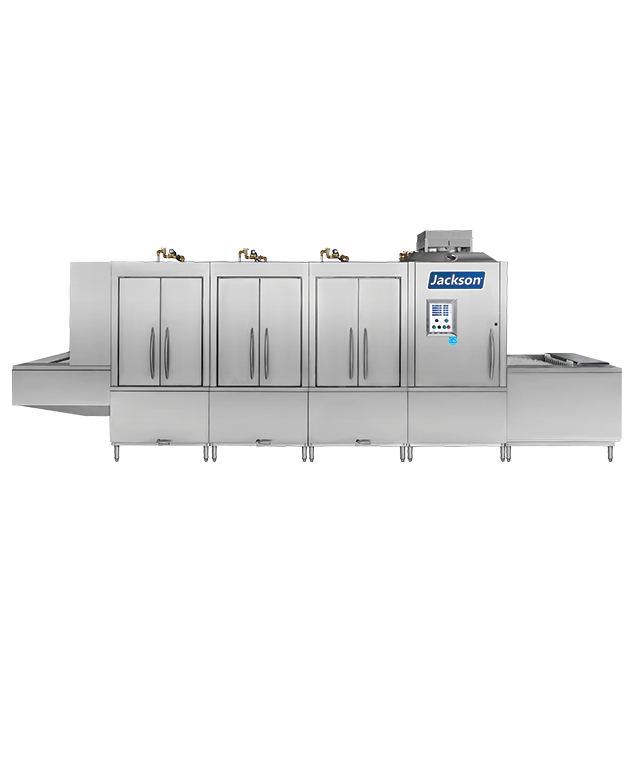

FlightStar® Flight-Type

Jackson’s FlightStar flight-type dishmachine is ENERGY STAR® certified, available in electric and steam, and goes above and beyond your traditional dishmachine. The FlightStar cleans up to 14,964 dishes per hour using ONLY 50 gallons of water per hour. Not only do you get the benefit of low water consumption, but we can customize and fit this powerful rackless conveyor dishmachine to meet your specific needs. Users will experience superior cleaning and whisper-quiet operation with low heat radiation to the dishroom. Low water consumption combined with flexibility in design makes the FlightStar a perfect choice for high volume operations across a multitude of industries.

- Low water consumption

- Adjustable rinse system with exclusive Rainbow Rinse – Econo Rinse (50 gph) for normal operation and Turbo Rinse (92 gph) for heavier soiled loads

- Hinged doors provide easy access into the unit for cleaning and servicing

- Digital LED control interface with service diagnostics

- Drive motor features a pulsed drive reverse to clear jams in the belt

- Durable, stainless steel construction

- Superior results and whisper-quiet operation with low heat radiation to the dishroom

- ENERGY STAR® certified

Width

222"

Depth

42"

Height

87.75"

Weight

3656 LB

Clearance

25"

Features

- ENERGY STAR® certified

- Uses 50 gallons (189.27 liters) of water per hour with hot water sanitizing rinse

- Two tank rackless conveyor with belt drive cleans up to 14,964 dishes per hour

- Conveyor belt drive is protected by an overload safety device and an automatic shut-down actuator

- Belt width of 29” (737 mm) and a maximum clearance of 25” (635 mm) throughout the machine

- Hinged doors are insulated and provide easy access into the dishmachine for cleaning and servicing

- Each door is equipped with a safety switch. If a door is opened during operation the switch will immediately shut down the pumps and belt

- Doors, hood and rear enclosure panels are stainless steel and double-wall insulated to reduce heat dissipation, outside surface temperatures, and decibel level while keeping inside water temperatures hot

- Adjustable rinse system for increased performance. Choose Econo Rinse for normal operation (50 gallons per hour), and Turbo Rinse for heavier soiled loads (92 gallons per hour)

- Exclusive Rainbow Rinse™ features arched, removable upper rinse arm that provides superior rinse action while reducing water usage

- Specially designed self-cleaning wash arms feature non-clogging, convex jet nozzles that deliver equalized water pressure and uniform cleanability

- LED digital temperature readout of each tank housed in the door of the electrical control panel. The readouts will continuously display the temperature of the pre-wash, wash, power rinse and final rinse

- Drive motor features a pulsed drive reverse to clear jams in the belt, activated from the unload end

- A ball valve in the drain line of each tank and interconnected to a common machine drain connection at either end of the machine

- Each tank will be automatically filled and maintained by a dual water level float. Water will be automatically added to the machine when required

- Large, removable scrap screens are easy to handle and fit inside all 20-55 gallon waste receptacles

- Pre-wash includes a deep-well removable scrap basket in addition to a large removable scrap screen

- Venting duct with sloped-to-rear draining reduces residue build-up from standing water

- Self-draining stainless steel pumps, impellers, and housings are readily accessible and serviceable

- Service access from front of machine

- Operator activated start-stop switches on both the load and unload ends and the control panel

- Belt tension adjustment

- Removable insulated panels to enclose the unit down to the base frame on both the front and rear of the machine

- All tanks and hoods constructed from durable stainless steel with a No. 3 finish and heliarc-welded

- Stainless steel frame, legs and feet

- A single, built-in 18” square (457 mm x 457 mm) indirect vent connection with a 0.19 hp exhaust fan mounted in a cleanable cross duct on the machine for exhaust steam removal and indirect vent connection

- 3” minimum wall clearance

Markets

- Education

- Healthcare

- Correctional Facilities